Aspectos más destacados

→ AMPLIA PANTALLA A COLOR

→ EXCELENTE VALOR

→ CONFIGURACION SIMPLIFICADA

F600

INSTRUMENTO DE PRUEBA DE FUGAS

Después de 47 años y más de 250,000 instrumentos instalados a más de 5,000 clientes en todo el mundo, ATEQ presenta su nuevo instrumento de prueba de fugas de gama de entrada por medición de presión absoluta: F600.

En su interior se encuentra lo último en tecnología de prueba de fugas para mejorar su control de calidad gracias a su renovado módulo electrónico, módulo de medición, interfaz, accesorios..

F600 : APLICACIONES

F600 : CARACTERÍSTICAS

- Medición de fugas por caída de presión diferencial

- Regulador mecánico o electrónico de vacío hasta 20 bar

- 128 programas

- Configuración en línea (a través de USB)

- 2 idiomas (inglés + otro)

- Calibración manual en el panel frontal con fuga calibrada

- Almacenamiento de datos en memoria interna o memoria USB

MODOS DE PRUEBA :

- Unidades de flujo (sccm, mm³/s, cm³/s, cm³/min, cm³/h…)

- Prueba de pasaje

- Otras pruebas, dependiendo de sus aplicaciones

MEDIO AMBIENTE :

Norma ROHS

FORMATO DE COMUNICACIÓN FLEXIBLE :

- RS232: impresora, Modbus RTU

- USB esclavo: supervisión PC (WinAteq 300, Sesame)

- USB maestro: memoria USB para transferencia (parámetros, resultados…)

- 6 Entradas / 6 Salidas programables de 24 V para automatización externa

- Regulador electrónico

CARACTERÍSTICAS DE MEDICIÓN :

| MEDICIÓN DE LA CAIDA DE PRESIÓN |

|---|

| Rango |

∆P Rango |

Exactitud | Resolución max. |

|---|---|---|---|

| Vacío 500Pa 5 bar 20 bar |

500 Pa (500 mbar) 1.00 kPa (vide, 500 mbar, 5bar, 20bar) 5.00 kPa (vide, 500 mbar, 5bar, 20bar) 10.00 kPa (vide, 500 mbar, 5bar, 20bar) 100.00 kPa (20 bar) |

+/- 1% Escala Completa | 1 Pa (500 Pa) 0.01 kPa (otros) |

Precisión: linealidad + repetibilidad + histéresis *Precisión de laboratorio opcional ** La presión máxima de prueba es de 3 bar.

F600 : ESPECIFICACIONES

F600 : OPCIONES

- 2 Salidas neumáticas para el control de conectores para el sellado de la pieza

- Volumen pequeño (F600 LP)

- Volumen pequeño/vacío (F600 LPV)

F600 : TECNOLOGÍA

Por mucho la tecnología más popular, la caída de presión diferencial utiliza un volumen de referencia para probar su pieza. Esto ayuda a compensar cualquier variación de presión ambiental o temperatura ya que ocurre en ambas piezas simultáneamente. Solo una fuga en la pieza de prueba provocará un movimiento en la membrana del transductor por diferencia de presión, lo cual será traducido en un valor de fuga.

La segunda ventaja de este método es que la precisión no disminuye aunque la presión de prueba aumente, ya que el transductor mide las diferencias de presión entre los dos circuitos, a diferencia de la tecnología tradicional que mide las caídas de presión en comparación con la atmósfera.

Como una versión simplificada de la tecnología anterior (caída de presión diferencial), la caída de presión estándar compara la presión en la pieza con la presión atmosférica.

Esta tecnología es utilizada cuando la aplicación no requiere una muy alta precisión o un tiempo de ciclo muy rápido. Este método utilizado está basado en la medida de la pequeña variación o caída de presión utilizando un sensor piezoeléctrico.

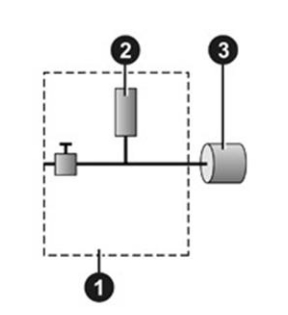

Prueba de Fuga y Modo desensibilizado

La presión de prueba es aplicada a la entrada de la pieza de prueba (3).

La medición es realizada por el sensor (2).

(1) Dispositivo

(2) Sensor de presión

(3) Pieza de prueba

F600: DOCUMENTOS

Por favor, contáctenos para solicitar su manual de usuario.

Próximamente