Aspectos más destacados

→ GRAN PANTALLA A COLOR

→ MÁXIMO RENDIMIENTO

→ COMUNICACIÓN MÚLTIPLE

ERD620

NUEVO PROBADOR DE VÁLVULAS COMPACTO

Después de 47 años y más de 250,000 instrumentos instalados a más de 5,000 clientes en todo el mundo, ATEQ presenta su revolucionario instrumento de prueba de fugas: ERD620. Cuenta con un nuevo módulo electrónico, nuevo módulo de medición, nueva interfaz, nuevos accesorios…

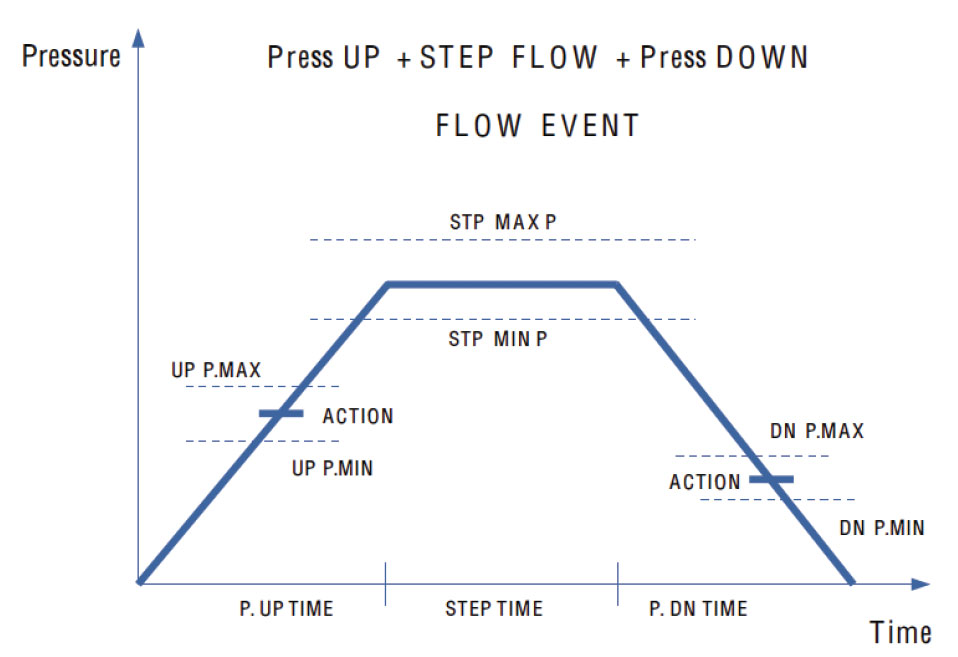

Todo esto se ha diseñado para mejorar su control de calidad. El propósito de este instrumento es generar una rampa de presión y estar a la espera de un evento como la aparición de un flujo (ejemplo: Apertura de una Válvula).

Una rampa descendente también puede ser detectado cuando la válvula es cerrada. El instrumento mostrará los eventps de presión y los comparará con los niveles de rechazo. Como opción, el evento de flujo puede ser reemplazado por un evento de contacto seco.

ERD620 : APLICACIONES

ERD620 : CARACTERÍSTICAS

- Medición de Flujo en prueba directa o indirecta

- Modo de medición continua

- Rango amplio de medición de flujo

- Unidades definidas por cliente, SI y Americano

- Medición en condiciones estándar o personalizada

- Flujo re calculado a la presión nominal

- Elemento de medición completamente integrado en un módulo

- 128 programas

- Regulador electrónico desde vacío hasta 10 bar

- Configuración en línea (a través de USB)

- 2 idiomas (inglés + otro)

- Almacenamiento de datos en memoria interna o memoria USB

MEDIO AMBIENTE :

Norma ROHS

FORMATO DE COMUNICACIÓN FLEXIBLE :

- RS232: impresora, Modbus RTU

- USB esclavo: supervisión PC (WinAteq 300, Sesame)

- USB maestro: memoria USB para transferencia (parámetros, resultados…)

- Opción Fieldbus: Profibus, DeviceNet, Profinet, Ethernet/IP. Modbus RTU

CARACTERÍSTICAS DE MEDICIÓN :

| MEDICIÓN DE FLUJO |

|---|

| Rango l/h | Exactitud hasta* | Resolución máx. |

|---|---|---|

| 5 | ±(2.5% F + 0.005 l/h) | 0.0001 |

| 30 | ±(2.5% F + 0.03 l/h) | 0.001 |

| 80 | ±(2.5 %F + 0.08 l/h) | 0.001 |

| 150 | ±(2.5 %F + 0.15 l/h) | 0.01 |

| 500 | ±(2.5 %F + 0.5 l/h) | 0.01 |

| 1.500 | ±(2.5 %F + 1.5 l/h) | 0.1 |

F= Flujo

ERD620 : ESPECIFICACIONES

ERD620 : OPCIONES

- 9 entradas / 5 salidas locales compatibles con instrumentos de la serie 5 (serie anterior).

- 6 entradas / 6 salidas programables de 24 V para automatización externa

- Capilar externo: Cerrado al puerto de prueba

- 2 Salidas neumáticas para control de sellos de conectores

- Tarjeta de memoria para archivar resultados (400,000).

ERD620 : TECNOLOGÍA

A veces, una fuga puede ser considerada como un “flujo pequeño”, o un flujo como una “fuga grande”. Cuando tu nivel de rechazo es tan grande para otras tecnologías, puede que sea necesario un probador de flujo laminar. El flujo se produce entre la linea de presión y el orificio de fuga de la pieza.

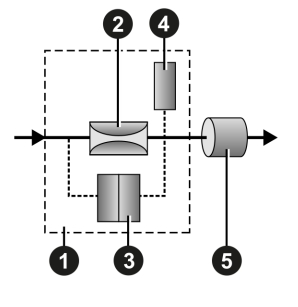

Nuestro instrumento cuenta con un elemento de flujo laminar a través del cual se conecta un transductor de presión diferencial.

Todo flujo genera un diferencia de presión entre la entrada y la salida del elemento de flujo laminar, y esta variación es medida por el transductor de presión.

Cuando un fluido (gas) entra en el dispositivo (1), se mueve a través de un tubo de flujo calibrado (2) que provoca una caída de presión. La caída de presión es medida por el sensor de presión diferencial (3). La presión de la pieza bajo prueba (5) es medida por el sensor (4).

ERD620: DOCUMENTOS

Por favor, contáctenos para solicitar su manual de usuario

Por favor, contáctenos para solicitar su Dibujo

Próximamente